For their capstone projects, UD senior engineering students built devices for use in healthcare, aerospace, manufacturing and more

Every year, senior engineering students at the University of Delaware face the greatest challenge of their academic careers. Preparation for work in their chosen field moves from the classroom to the engineering trenches, where they must use all of their training to solve real-world problems by designing and building real-world prototypes and products — all while facing real-world obstacles.

Never were these obstacles greater than in the fall of 2020.

“This is one of the best, most well-established senior capstone programs in the country, and we put our kids up against those from any university considered an engineering powerhouse,” said Jenni Buckley, associate professor of mechanical engineering and herself a product of this program at UD. “This year, I am especially blown away by their grit and their perseverance.”

Engineers Week 2021, which is sponsored by the National Society of Professional Engineers and runs from Sunday, Feb. 21 through Feb. 27, is an ideal time for celebrating the work accomplished during Senior Design. All UD mechanical and biomedical engineers are required to take the semester-long course, although a smattering of the University’s environmental and electrical engineers join, too, making the experience truly interdisciplinary. At the beginning of the term, each participating Blue Hen selects from a predetermined list a project they would like to complete. The students choose a sponsor, which could be a nonprofit organization, a clinical partner, a member of UD’s faculty or a local, national or international company with a big problem to solve.

Based on these interests, the students are broken into teams — 41, this year. These groups then serve as independent consulting firms hired to do a specific job. Typically, these jobs are “the long-shot stuff,” Buckley said. “They are the things a sponsor has not had the time or energy or creativity for, so they put a team of students on it to see what fresh ideas they can come up with.” It is a strategy that pays off — in an average year, about a quarter of the student prototypes result in a patent.

Of course, this has not been an average academic year. Because of the coronavirus (COVID-19) pandemic, most courses at UD transitioned to a virtual format in the fall of 2020. Senior Design was one of the few with on-campus access, but the prototyping lab was limited to a handful of students at a time. Additionally, because of a restructured academic calendar, class members lost out on two weeks of prototyping time. But expectations for the students — including those held by the students themselves — remained high. Despite all of the challenges, participants in Senior Design successfully created everything from a new-and-improved face mask for combatting COVID-19 to a simplified process for building bamboo wheelchairs for Paralympians in Ghana to an efficient training device for technicians learning to put down chickens humanely.

“Struggle is part of the process,” said Catherine Fromen, assistant professor in the Department of Chemical and Biomolecular Engineering. “In fact, great things come out of it. Senior Design allows students to build resiliency, to take these setbacks in stride and come up with creative workarounds. In this sense, the course is practical for anything they are going to do in the rest of their lives.”

For one of the projects Fromen sponsored in the fall, students were tasked with building upon work done in her lab. Doctoral candidate Ian Woodward had developed a 3-D printed model of human lungs, a tricky thing to do considering the complexity of these organs — the surface area of one pair, if laid out flat, would equal that of a tennis court. Such a model, when refined, will allow researchers to see exactly where the aerosols of potential, inhalable medicines will land in the lungs and, therefore, what effect these medicines might have on certain diseases. Translation: This invention could one day lead to customized inhalers for treating conditions like emphysema, lung cancer, even COVID-19. The Senior Design team worked on a frame for this device, as well as a motorized system for helping it respirate.

“This is an experience I wouldn’t trade for anything,” said Paige Gilbride, a biomedical engineering major. “Not only is this program amazing academically, the faculty interacts with and knows their students on a personal level. The support — through each success and challenge — was wonderful.”

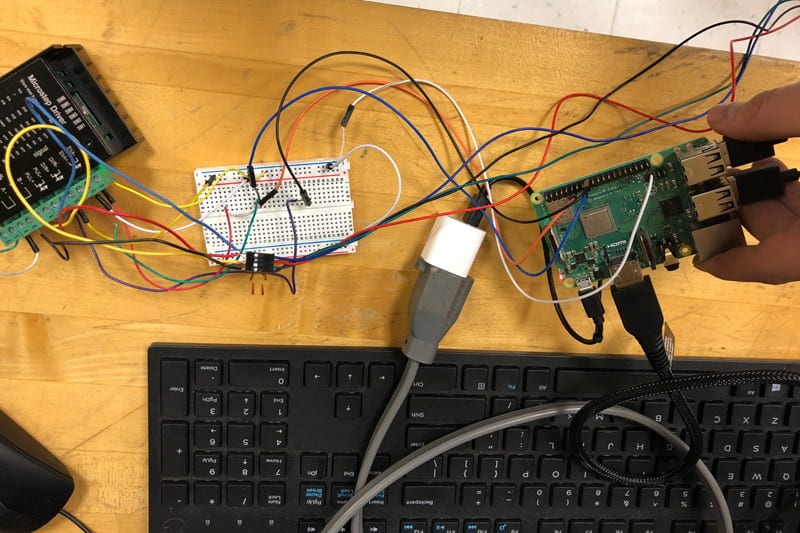

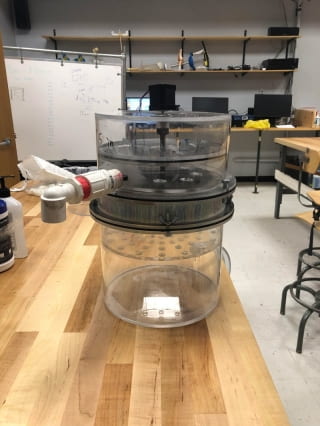

Another project Fromen sponsored in the fall also involved the lungs — this time, students built from scratch a first-of-its-kind motorized chamber that mimics the process of inhaling from an e-cigarette and onto a plate of cells. The idea is to give researchers a clearer window into the damaging effects of vaping, a field of study still in its infancy.

“It is really cool to think this device could be helping people someday,” said Mason Mostrom, a computer engineering major. “Working on this was such a rewarding experience, and it’s making me all the more excited to get into my career and start off strong.”

According to Ashutosh Khandha, assistant professor of biomedical engineering, this presence of mind before entering the job market is one of the perks of Senior Design.

“Some of these next-generation engineers have already managed to secure jobs based on the experience they had in this course, which is really commendable,” Khandha said. “So being able to work on real-world problems not only gives them confidence entering the workforce, it gives them the satisfaction of feeling like they’re contributing something meaningful that’s going to have a lasting impact.”

Consider Pavithran Naicker, a biomedical engineering major. For a project sponsored by the Newark-based Elasthetics company and advised by Khandha, he worked on a pioneering orthosis device meant for children with cerebral palsy, to help them walk longer and more comfortably. This apparatus, worn like a boot, is special because it incorporates an electronic component — sensors measure how the leg is moving and where it needs support. This information is then transferred to artificial muscles in the orthosis that will extend or contract based on feedback.

“I don’t mean to sound cringey or sentimental here, but I feel honestly blessed that I got to work on this,” said Naicker, who hopes to launch his own medical tech company one day. “Something like Senior Design puts into perspective how much you’ve learned and just how much you can do with that.”

For Isabella Krynyckyi, the sky is the limit — literally. Her team’s task, sponsored by the Aero Society of Automotive Engineers, has been to build a functional, remote-controlled model airplane that will colonize Mars… or, at least, simulate the colonization of Mars. In a competition in June in Lakeland, Florida, against other engineering teams from across the country, their team’s plane will not only need to lift off and land successfully, it will need to release water bottles (supplies), Nerf footballs (habitats) and an autonomous glider carrying ping pong balls (colonists) in designated locations.

“This project solidified my future plans,” said Krynyckyi, adding that she’ll complete UD’s 4+1 program in mechanical engineering, which will result in a master’s degree, before trying for a career with an aerospace company like ILC Dover, SpaceX or NASA. She might, one day, just have a hand in colonizing the actual planet of Mars.

“I definitely got my dream senior project,” she said. “I know engineering in general has a reputation for being really competitive and every-man-for-himself, but the mechanical engineering department at UD does a great job of building a sense of community and teamwork. The faculty and students make it feel like home.”

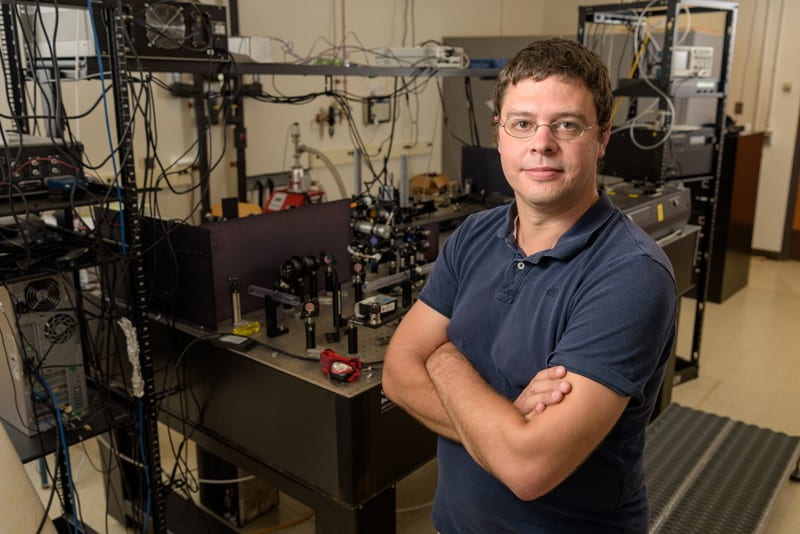

In December, all of these Senior Design projects and more were presented at a virtual showcase while proud friends, family members and instructors tuned in. Joseph Feser, associate professor of mechanical engineering, looked on as the student teams he advised explained their inventions to the crowd. For Siemens Healthineers, a global leader in developing healthcare solutions, one group designed functional microscale devices that may someday replace the large and expensive machinery currently used for blood diagnostics.

“You’ve got coding, manufacturing, optics, fluidics — there are a lot of different aspects to a project like this,” Feser said. “And, at the end of the day, this was just four students who had never done anything like this before. It is amazing what they accomplished.”

Despite all the obstacles of an unprecedented year, he added, these and all members of the Senior Design course rose to the challenge with the mettle and vision of engineers.

“Not a lot of great stories came out of 2020,” Feser said. “But this is one reason to celebrate.”

Article by Diane Stopyra | Photos by Kathy F. Atkinson and Evan Krape and courtesy of Mason Mostrom, Ashutosh Khandha and Isabella Krynyckyi | February 19, 2021